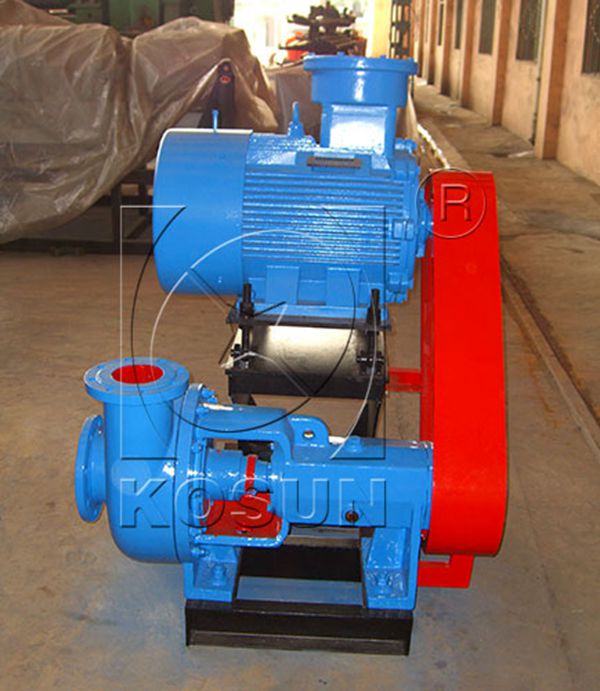

There are so many methods for you to make sure a longer service life of centrifugal pump:

1. Before and during operation, the insulation resistance of the motors must be checked regularly, and the grounding condition should be checked to see if the cable skin is broken;

2. Check whether the centrifugal pump line and the joint are loose. Turn the centrifugal pump by hand, check whether the centrifugal pump is flexible;

3. Add bearing lubricating oil into the bearing body. Observe the oil level at the center line of the oil mark;

4. Try to control the flow rate and head of the centrifugal pump within the scope indicated on the label, so as to ensure the operation of the centrifugal pump at the highest efficiency point, in order to obtain the maximum energy saving effect;

5. During the operation of the centrifugal pump, the bearing temperature shall not exceed the ambient temperature of 35℃, and the maximum temperature shall not exceed 80℃;

6. If abnormal sound is found in the centrifugal pump, stop immediately to check the reason;

7. When the centrifugal pump is to stop using, first close the gate valve and pressure gauge, and then stop the motor;

8. The lubricating oil of the centrifugal pump shall be changed for 100 hours within the first month of operation. After that, the oil shall be changed every 500 hours;

9. Often adjust the packing gland to ensure normal drip leakage in the packing room (it is advisable to make drip leakage);

10. Check the wear condition of the shaft sleeve regularly, and replace it in time after big wear. Horizontal centrifugal pump to check the pump coupling regularly, the unit overhaul is generally one year;

11. When the centrifugal pump is in use in the cold winter, after stopping the pump, unscrew the waterproof screw at the bottom of the pump body to clean the medium. Prevent frostbite;

12. When the centrifugal pump is out of use for a long time, all the pumps should be disassembled and wiped dry. The rotating parts and joints should be coated with grease for proper protection;

13. The spare pump should be replaced regularly to reduce the chance of dampness of motor stator windings.

Kosun- China Solids Control Leader&Drilling Waste Management Expert

Tel.: +86 29 87304914

Email: sales2@adkosun.com

Contact person: Jinbo Zheng

Contact person: Jinbo Zheng