At present, the international definition of solid control equipment and solid control system for oil drilling is as follows: the equipment and system used for the recovery of drilling fluid (mud) carried to the surface through the wellhead for purification and separation.Solid control system can be carried through pipes from wellhead to the drilling fluid (mud) on the ground in relatively larger cuttings volume, barite and other large efficient separation of solid particles, and get out of the drilling fluid solid particles, the processing of the drilling fluid (mud) can be reused in the process of drilling.This can reduce the cost of drilling, and for environmental protection has a great role.

KOSUN has now been sold all over the world many sets of oil and gas drilling solids control equipment, in the field of this kind, we each made a corresponding adjustment of solids control equipment, purification treatment effect is good, and can according to customer demand, to adjust the whole system, meet the use of different clients.

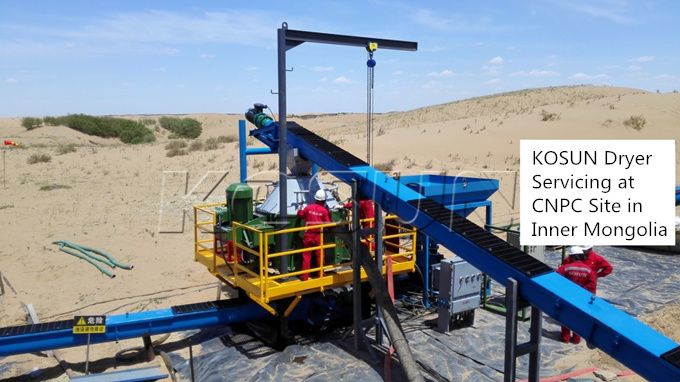

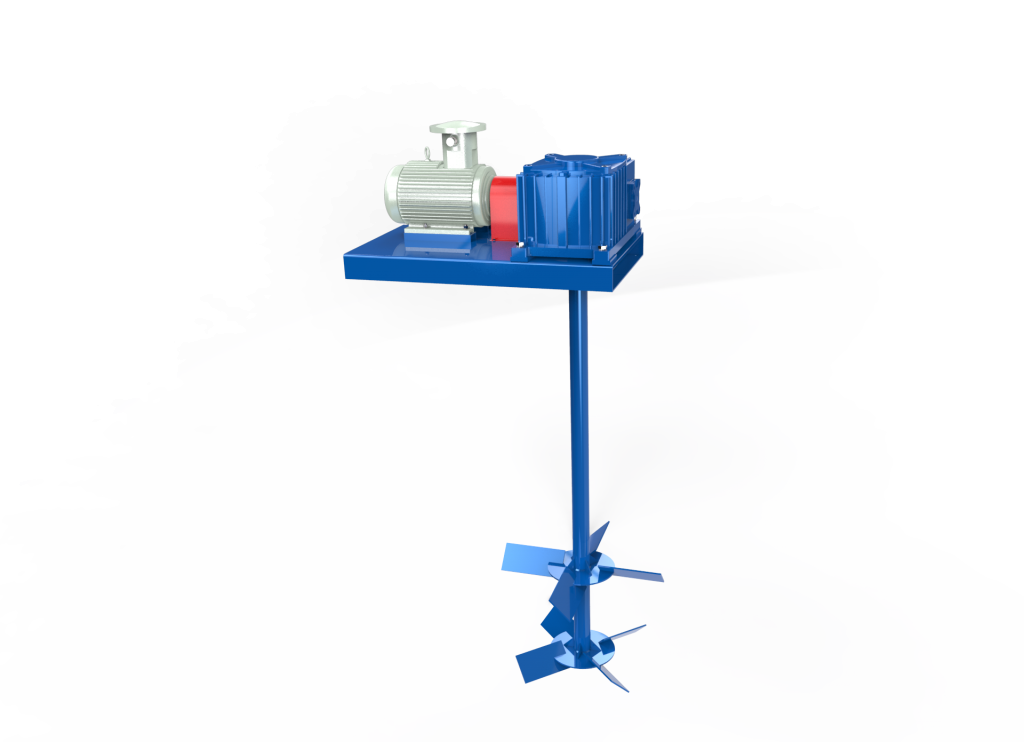

KOSUN manufactures all solid control equipment for drilling and construction mud treatment, including shale shaker, desander, desilter and centrifuge. In addition, KOSUN also manufactures drilling and construction waste mud treatment equipment, such as vertical cuttings dryer, high G dry screen and waste slurry treatment centrifuges. The centrifuge can be used to separate high specific gravity solids and low specific gravity solids.

For different drilling mud treatment and construction:

1. The oil and gas drilling fluid treatment

2. Coal bed methane drilling mud

3. The mud mud/trenchless horizontal directional drilling engineering

4. Tunneling mud treatment

5. Building pile mud treatment

6. The well drilling mud

7. The mining industry and diamond drilling mud

8. Geothermal drilling mud