Using durable shale shaker screens in harsh environments offers several advantages, which can significantly improve the performance and longevity of the shale shaker system. Here are some key advantages:

1, Enhanced Screen Life:

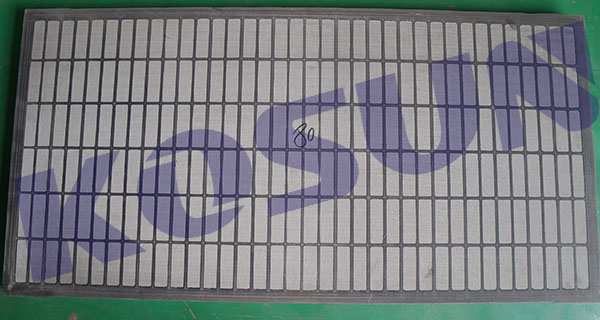

Harsh drilling environments often involve abrasive materials, high temperatures, and challenging drilling conditions. Durable shale shaker screens are specifically designed to withstand these conditions and have increased resistance to wear and tear. They are constructed using robust materials and innovative manufacturing techniques, resulting in extended screen life. By using durable screens, operators can reduce the frequency of screen replacements, leading to cost savings and improved operational efficiency.

2, Improved Solids Control Efficiency:

Durable shale shaker screens maintain their integrity and screening effectiveness even in harsh environments. They can effectively separate and remove a wide range of solid particles, including fine particles and larger cuttings. With improved solids control efficiency, the screens help maintain the desired drilling mud properties, such as density and viscosity. This contributes to better drilling performance, reduced downtime, and minimized equipment wear and tear.

3, Reduced Screen Blinding and Plugging:

In harsh drilling conditions, screen blinding and plugging are common challenges that can hinder solids separation and reduce shale shaker efficiency. Durable screens are designed with features that resist blinding and plugging, such as specialized mesh configurations and anti-blinding mechanisms. These screens can effectively prevent the accumulation of solids and minimize the need for frequent cleaning or unclogging, resulting in uninterrupted operations and improved overall productivity.

4, Optimal Performance in Extreme Temperatures:

Some drilling operations encounter extreme temperature variations, either in extremely cold or hot environments. Durable shale shaker screens are engineered to withstand temperature extremes without compromising their performance. They are constructed using materials that maintain their strength and flexibility, ensuring reliable screening even in challenging temperature conditions. This allows for consistent solids control performance and eliminates the risk of screen failure due to thermal stress.

5, Resistance to Corrosion and Chemical Attacks:

Harsh drilling environments may involve exposure to corrosive drilling fluids and aggressive chemicals. Durable shale shaker screens are manufactured using corrosion-resistant materials, coatings, or alloys that provide enhanced resistance to chemical attack. This protects the screens from premature degradation, maintains their structural integrity, and ensures reliable solids separation even in corrosive environments.

6, Improved Environmental Stewardship:

Durable shale shaker screens contribute to environmental stewardship in several ways. Their extended lifespan reduces the frequency of screen replacements, resulting in reduced waste generation. Additionally, their efficient solids control capabilities minimize the discharge of drilling cuttings and fine particles into the environment, reducing the environmental impact of drilling operations.

7, Cost Savings:

The use of durable shale shaker screens in harsh environments can lead to significant cost savings in multiple ways. The longer screen life and reduced replacement frequency result in lower screen procurement and maintenance costs. Improved solids control efficiency reduces mud consumption, minimizing the need for fresh mud and associated costs. Additionally, the reduction in screen blinding, plugging, and equipment downtime improves operational efficiency and productivity, leading to cost savings.

In summary, durable shale shaker screens offer advantages such as extended screen life, improved solids control efficiency, resistance to blinding and plugging, optimal performance in extreme temperatures, corrosion resistance, environmental benefits, and cost savings. Investing in high-quality and durable screens tailored for harsh environments can positively impact drilling operations, ensuring efficient solids control and reducing operational costs.