Shale Shaker is a filtrable machine separation equipment for mud solid phase treatment. It is a new type of efficient screening equipment for separating solid phase particles with mud particle size greater than 76um. It is widely used in oil drilling, coal mining, shield construction, HDD trenchless and other industries.

Kosun oval shaker face

Kosun ES series vibrating screen adopts long cylinder vibration motor as power source, superior performance, reasonable structure, stable operation, long life and low maintenance cost. Under the same conditions, compared with other types of vibrating screen, the drilling mud treatment capacity and sand transport chip removal capacity can be greatly improved, and can effectively overcome the “sieve blocking” and “sieve paste” phenomenon.

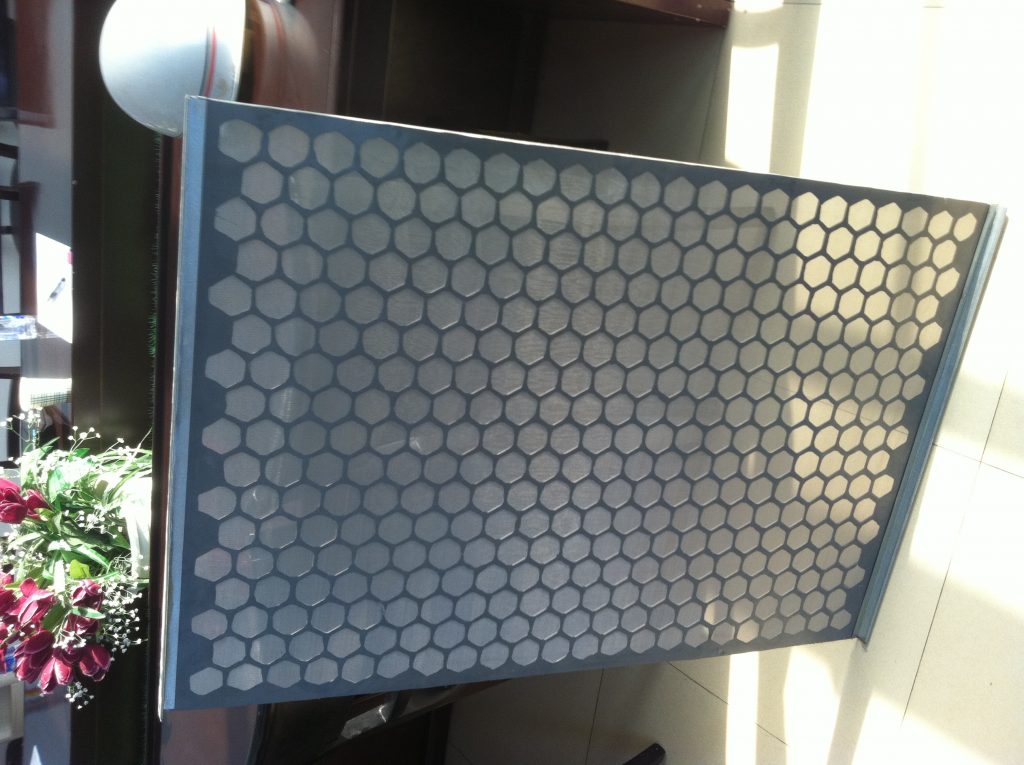

Kosun ellipse vibrating screen side

ES series vibrating screen is also the first solid control equipment for handling drilling mud

It has the following features and advantages:

1, the balanced elliptical trajectory can effectively reduce the phenomenon of sieve blocking, to ensure the screening rate.

- It is beneficial to improve the delivery speed of drilling cuttings in the viscous drilling mud and prevent the paste sieve.

3, can deal with large gravity high viscous drilling fluid.

- Get drier cuttings.

5, the composite screen has a longer screen life.

6, fast tensioning system, easy to replace the screen.

7, -1° ~ +5° screen frame Angle adjustment device.

8, the feed box has two kinds of weir type and box type.

Back of Kosun shaker

The structure and working principle of the vibrating screen:

The vibrating screen is generally composed of a vibrator, a screen box, a support or suspension device, and a transmission device.

When working, the exciter generates periodic exciting force, so that the screen box vibrates, thereby driving the material on the screen to be stratified. Smaller particles fall through the screen into the lower layer, while larger particles are separated and moved along the screen surface to the discharge port.

Xi ‘an KOSUN Machinery (KOSUN) provides solid waste treatment related products and services, applied in oil and gas extraction, construction machinery, industrial sludge treatment, river and lake sludge and urban sludge treatment and disposal, soil remediation, tailings comprehensive utilization and other seven fields. Looking forward to serving you! Welcome to call for consultation!