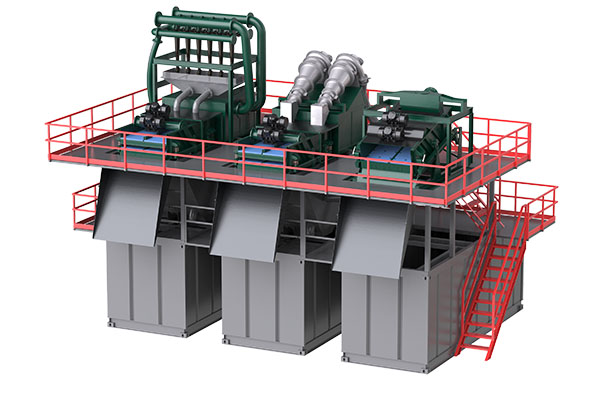

The screen mesh size of a shale shaker is a critical factor that directly affects its efficiency in solids control during drilling operations. Selecting the appropriate mesh size ensures optimal separation of drilling solids, improves drilling fluid quality, and enhances overall operational performance. In this article, we will provide valuable insights and guidelines on how to choose the right screen mesh size for a shale shaker.

1, Understand the Basics of Screen Mesh Size:

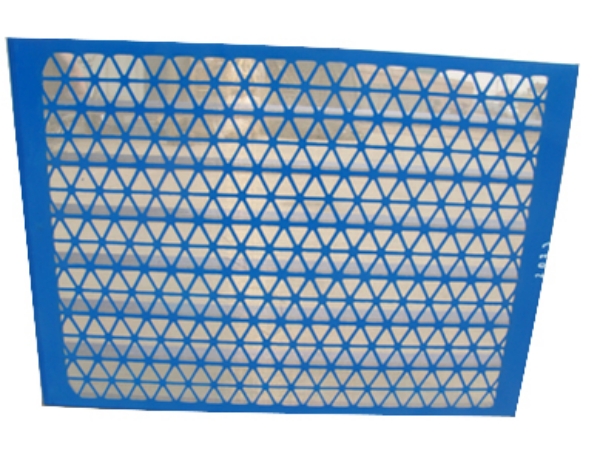

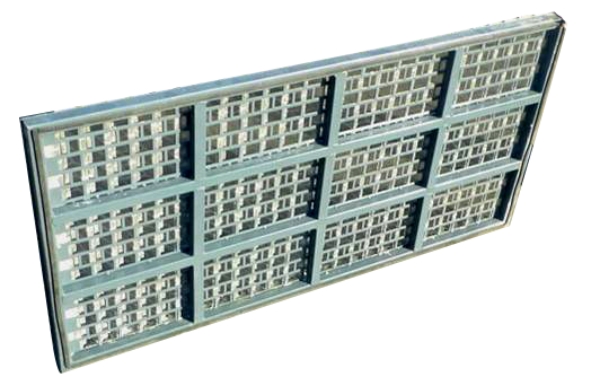

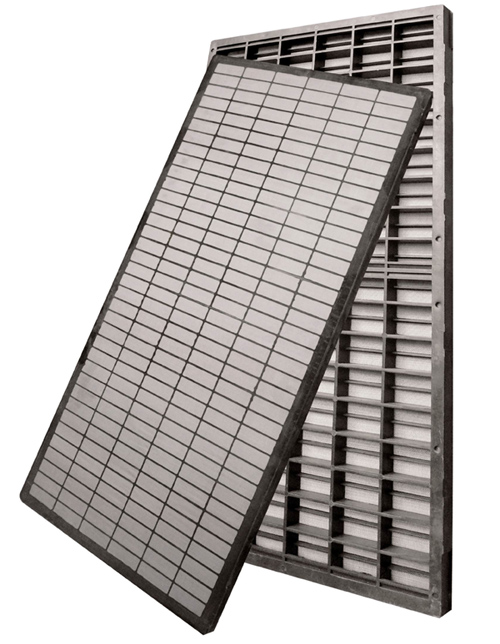

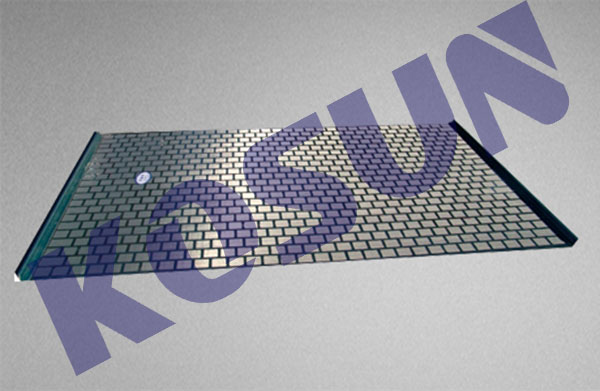

Screen mesh size refers to the number of openings per linear inch in a square inch of screen. It is denoted by the mesh count, where a higher mesh count indicates smaller openings and finer particle separation. For example, a 200 mesh screen has smaller openings compared to a 100 mesh screen.

2, Consider the Drilling Application and Formation Characteristics:

The choice of screen mesh size should be based on the specific drilling application and the characteristics of the formation being drilled. Consider the following factors:

a) Formation Size and Composition: Determine the size distribution and composition of the drilled solids in the formation. Finer formations may require finer mesh sizes to effectively separate smaller particles.

b) Drilling Fluid Properties: Analyze the properties of the drilling fluid, such as viscosity, density, and rheological behavior. These properties can influence the drilling solids’ settling characteristics and the required mesh size for efficient separation.

c) Drilling Conditions: Take into account the anticipated drilling conditions, including the expected volume and type of drilling solids. Higher concentrations of fine particles may necessitate a finer mesh size.

3, Evaluate Shale Shaker Performance and Cut Point:

Understanding the performance capabilities of the shale shaker is crucial in selecting the appropriate screen mesh size. Consider the following factors:

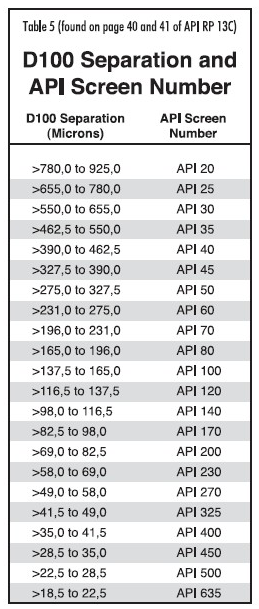

a) Screen API Designation: Shale shaker screens are often assigned an API designation, which specifies the range of particle sizes that can be efficiently separated by the screen. For example, an API 60 screen is designed to remove particles larger than 250 microns.

b) Cut Point Requirement: Determine the desired cut point, which is the particle size at which the screen can efficiently separate the solids. This depends on the drilling operation and the desired level of solids control. Finer mesh sizes are suitable for achieving lower cut points.

4, Consult Manufacturer Recommendations and Industry Standards:

Manufacturers of shale shakers typically provide guidelines and recommendations regarding suitable mesh sizes for their equipment. Consult these guidelines to ensure compatibility and optimal performance. Additionally, adhere to industry standards and regulations related to screen mesh sizes for specific drilling operations or geographical regions.

5, Consider Field Experience and Testing:

Gather information from field experience or conduct testing to evaluate the effectiveness of different screen mesh sizes. Collaborate with drilling experts or industry professionals who have experience with similar drilling conditions. Field trials can provide valuable insights and help identify the optimal screen mesh size for specific applications.

6, Optimize Efficiency and Solids Control:

Achieving an optimal balance between screen capacity and solids control efficiency is crucial. While finer mesh sizes provide better separation for smaller particles, they may reduce screen capacity and potentially increase the risk of screen blinding. Consider the trade-offs and strike a balance that maximizes solids control while maintaining acceptable drilling fluid flow rates.

Selecting the right screen mesh size for a shale shaker is essential for efficient solids control and optimal drilling performance. By considering the drilling application, formation characteristics, shale shaker performance, and consulting manufacturer recommendations, operators can make informed decisions. Balancing screen capacity, solids control efficiency, and cut point requirements will ensure effective particle separation, improved drilling fluid quality, and enhanced operational efficiency in drilling operations.

Tags: screen mesh size for shale shaker, shaker Screen Mesh Size, Solids Control, suppliers, manufacturers, factory, wholesale, buy, price, quotation, bulk, for sale, companies, stock, cost.

Related Products:

https://www.kosun.com/products/Product-Accessories/shaker-screen.html